Standard Spells Out Crash Testing Method for Protective Guarding

By: Maureen Paraventi

A standard published earlier this year is designed to improve safety in the material handling industry, while also leveling the playing field when it comes to evaluating the effectiveness of industrial guardrail barriers and posts. The standard, ANSI MH31.2-2021, provides a crash testing method for evaluating the performance characteristics of the products.

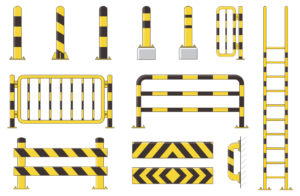

Found in many industrial and warehouse environments, industrial guardrail barriers and barrier posts are intended to prevent workers and other pedestrians from being struck by vehicles, among other things. They are typically mounted to the ground-level concrete floor slab at a safe distance away from pedestrian aisleways, vital equipment or critical infrastructure.

The standard has similarities to test methods found in ASTM F3016, but uses different impact velocities and surrogate test vehicle mass in order to replicate the kind of powered industrial truck impacts that can occur in manufacturing, warehousing or distribution environments. Prior to ANSI MH31.2-2021, there were no standardized parameters for manufacturers of guardrail barriers and posts to use when performing independent testing of their products. The new standard is designed to make it easier for end users to compare products and determine which ones are appropriate for their particular applications.

ANSI MH31.2-2021 was published by the Protective Guarding Manufacturers Association (ProGMA), an MHI industry group that focuses on protecting people, product and facilities, as well as promoting best practices in the industry. ProGMA worked on developing the standard with Texas A&M Transportation Institute (TTI), which addresses complex transportation challenges. It was a natural fit, since the TTI testing laboratory is capable of conducting the crash testing outlined in the standard.

TTI has a history of involvement with guardrail safety. A product that originated in the TTI lab figured heavily in a 2008 incident in Texas, a man driving a pickup truck lost control of his vehicle when it began hydroplaning on a rain-soaked highway. Twenty-three-year-old Garrett Placke was driving home from his niece’s christening when the life-threatening incident occurred.

“I knew I was going to hit the guardrail head-on at 65 [miles per hour], so I was expecting a really big slam,” said Placke. “Remarkably, my truck stopped very quickly, and I couldn’t believe I wasn’t hurt.” The guardrail absorbed the truck’s impact and prevented it from heading over a steep embankment into a creek. The guardrail Placke’s truck struck was an end terminal called ET-PLUS, designed by TTI and manufactured by Trinity industries. Ironically, the incident occurred near Texas A&M’s Riverside campus – not far from where the guardrail was designed.

Determining Your Needs

Within the material handling space, the type of industrial guardrails and barriers should be chosen based on their purpose and the location where they’ll be used. Will the protective guarding need to:

- Prevent pedestrians from being struck by powered industrial trucks (PITs) in an area of the plant, warehouse or distribution center with a lot of PIT traffic?

- Separate different areas of the facility in a highly visible way?

- Keep employees at a safe distance from hazardous machinery?

- Protect assets?

- Protect columns from being struck and damaged by PITs?

- Protect overhead door tracks on docks from being damaged?

- All of the above?

Depending upon specific needs, single and double guardrails with pedestrian gates may be the best fit for your facility or one area of your facility. Short, sturdy vertical posts called bollards, with flexible and bounce-back options are useful for preventing vehicles from entering an area while allowing personnel to pass through. All of the above are available in both steel and polymer versions. Other guarding options include column protectors, guarding that prevents items from falling onto conveyor systems, dock door protection and dock lift gates. In addition to choosing the right kind of protective guarding, it’s important that it be spaced and installed correctly. It’s important to remember that even with a company that has adequate safety training and procedures, a worker could suffer a devastating injury – or worse – if a moment’s inattention causes him or her to stray into the path of a PIT. Having highly visible, traffic-strength guardrails in place reduces the risk of such an incident. Likewise, a new, inexperienced employee might not be aware of the need to maintain a certain distance from dangerous machinery or equipment. Protective guarding removes the element of risk. An additional benefit of protective guarding: it protects assets, columns, conveyor systems and dock lift gates, reduces repair costs and downtime.

ProGMA has a protective guarding search tool at: https://www.mhi.org/progma/technologies that can help companies find products and technologies that fit their needs. It also provides lists of manufacturers that provide those products.

The standard, ANSI MH31.2-2021, is available at: http://imis.mhi.org/. WMHS