ANSI MH29.1:2012: Safety Requirements for Industrial Scissors Lifts

“Over 20 years ago, Advance Lifts and a number of other leading manufacturers of industrial scissors lifts formed a group that worked on developing the first version of Safety Requirements for Industrial Scissors Lifts. This became known as the ANSI MH29.1 standard. Advance Lifts has continued to be active in the development of the subsequent revisions to the standard and, in 2015, the International Code Council (ICC) incorporated ANSI MH29.1 as a reference standard in section 3001.2 in chapter 30 of the International Building Code (IBC). All of the Advance Lifts scissors lifts products are designed, tested and manufactured to comply with ANSI MH29.1. Consequently, when we ship a product to a customer, we are confident that we are providing them with reliable, durable and safe products. ANSI MH29.1 is a very important part of our company’s business philosophy.”

Advance Lifts, Inc., 800-843-3625, www.advancelifts.com

About the Standard

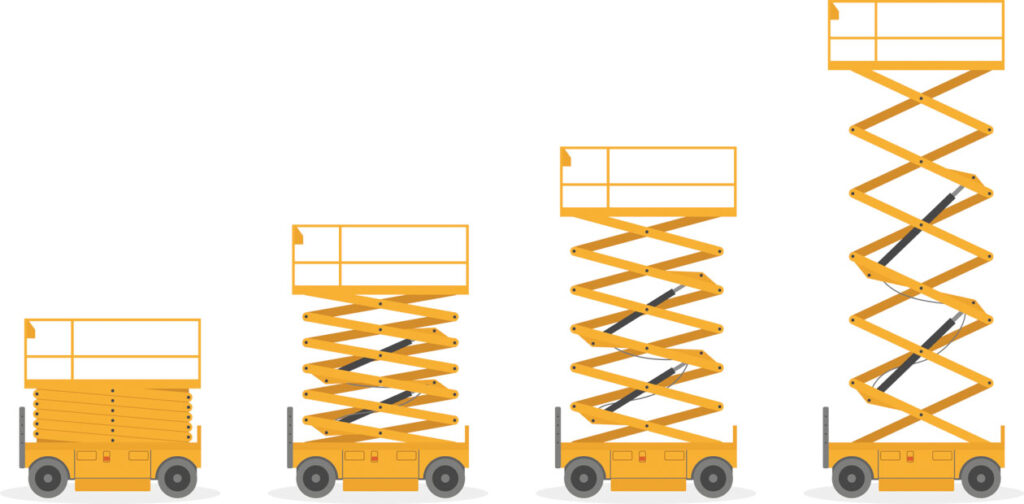

This standard applies to industrial scissors lifts that are raised and lowered by means of hydraulic, pneumatic or mechanical actuation. These industrial scissors lifts are intended for commercial applications on firm and level surfaces and may be either stationary or mobile and used to position, feed, transfer, load or unload materials and/or personnel. Industrial scissors lifts are available in a range of capacities, sizes and travels, and include dock lifts, work access lifts and lift tables. (ANSI: https://webstore.ansi.org/preview-pages/MHIA/preview_ANSI+MH29.1-2012.pdf)

This standard does not apply to: (1) Lift tables that do not incorporate scissors type mechanisms. (2) Aerial or work platforms as covered by ANSI/SIA A92. (3) Elevators and equipment covered in ANSI/ASME A17.1, safety code for elevator and escalators (The National Elevator Code). (4) Vertical reciprocating conveyors such as those covered in ANSI/ASME B20.1, Safety Standard for conveyors and related equipment. (4) Vertical lifts intended for transportation of a mobility impaired person only as covered in ANSI/ASME A18.1 – The Safety Standard for Platform Lifts and Stairway Chairlifts. (5) Automotive vehicle service lifts such as covered in ANSI/ALI ALIS, ANSI/ALI ALOIM, and ANSI/ALI ALCTV. (6) Vehicle transport lifts as covered in ANSI/ASME PALD, Part 17. (7) Performing art lifts such as stage and orchestra lifts. (ANSI: https://webstore.ansi.org/preview-pages/MHIA/preview_ANSI+MH29.1-2012.pdf)

The standard includes responsibilities of manufacturers, owners/users and operators and covers basic principles, inspection and maintenance details, what training should include, workplace inspections and operator warnings and instructions, among other items.

History of the standard

ANSI MH29.1 was developed to provide a comprehensive safety standard and establish a minimum design and performance criteria to ensure the safe application and utilization of industrial scissors lifts. It is intended to serve as a guide for designers, manufacturers, sellers, installers, equipment specifiers, owners, users and governing bodies of industrial scissors lifts. The newest revision of the standard, MH29.1:2012 was released by Lift Manufacturers Product Section (LMPS) Industry Group of the MHI. It made changes and additions to definitions contained in the standard intended to address confusion and overlap in the earlier version and provide further delineation between industrial scissors lifts and aerial type lifts. The responsibilities of manufacturers, users, owners and operators have been reordered, consolidated and enhanced. Lastly, the requirements within the standard have been revised where needed to ensure they are stated using mandatory language. This revision contains a new section on operator responsibilities and modifies values related to the indicator bars in the section on platform protection. (ANSI: https://webstore.ansi.org/preview-pages/MHIA/preview_ANSI+MH29.1-2012.pdf)

Select the right equipment for the task

One of the most important ways to ensure safety is to choose the right lift for the application. To do this, it is necessary to take into account:

- The capacity: the total weight that will be placed on a unit. In order for a unit to be safe, it must be able to lift its maximum loaded capacity.

- The nature of the load: what the load consists of, the weights of the load components, the center of gravity of the load, if it is not centered on the load, and the physical dimensions of the load

- Means of loading and unloading: how loads are transitioned onto and off of the lift. These movements determine the “edge loading” and/or “impact” that the structure must sustain and they may contribute to off centered load conditions during the lifting cycle. The most common ways in which loads are transitioned on and off lifts are: rolled on/ rolled off – with a wheeled vehicle or cart; slid on/ slid off – as in sheet feeding operations or conveyor operations; placed on/ picked off – as in stacking operations or crane loading.

- Travel and lowered height: Travel refers to the vertical movement of the unit. Units with excess travel are chosen for some applications, so that longer platforms can be made available.

- Platform size

- Speed requirements: In most cases, the standard speed of a lift model is satisfactory for most applications.

Consulting with a manufacturer will help determine the right lift for an application.

For more information

- Details about ANSI MH29.1-2020: Industrial Scissors Lifts are available at: https://blog.ansi.org/ansi-mh29-1-2020-industrial-scissors-lifts/.

- OSHA has an eTool that contains information about how to safely use, position and maintain scissor lifts. You can access it at: https://www.osha.gov/etools/scaffolding/scissor-lifts/