Meeting OSHA Requirements with Safety Signage

By: Jane Marsh, Contributor

An organized society depends in part on the state of its infrastructure. Some workplaces are simply vital, whether maintaining roads and bridges or stowing and picking orders in warehouses.

An organized society depends in part on the state of its infrastructure. Some workplaces are simply vital, whether maintaining roads and bridges or stowing and picking orders in warehouses.

It falls to employers to provide as safe a workplace as possible, whether or not workers face physical risks at work, like heavy equipment or speeding motorists. The U.S. Bureau of Labor Statistics recorded 4,764 deadly workplace injuries in 2020, plus an additional 2.7 million nonfatal workplace injuries.

One injury or death is too many. Here are the essentials that engineers, worksite supervisors and warehouse managers should know about regarding OSHA requirements for safety signage.

1. Learn Which Standards Apply

There are two primary sets of written guidelines for safety tags and signs:

- OSHA:CFR 1910.145

- ANSI:Z535

The OSHA rules are based on original ANSI standards, which have been revised several times to better reflect the needs of modern industry.

Such guidelines typically see revisions every five years. Employers already using signs compliant under previous iterations may voluntarily update them to reflect the changes, but this is not required.

These guidelines demystify whether signs must be used in a particular environment, their physical layout and size, and the kinds of colors and phrases that effectively communicate about hazards clearly and succinctly.

2. Understand the Elements of Compliant Signage

Several essential elements go into an effective and compliant safety tag or sign.

Header (Signal Word)

This is located at the top of the sign. Examples include “warning,” “danger,” “caution” or “notice.”

Depending on the severity of the hazard, the background color could be red, orange or yellow. A blue background denotes the chance for property or bodily damage.

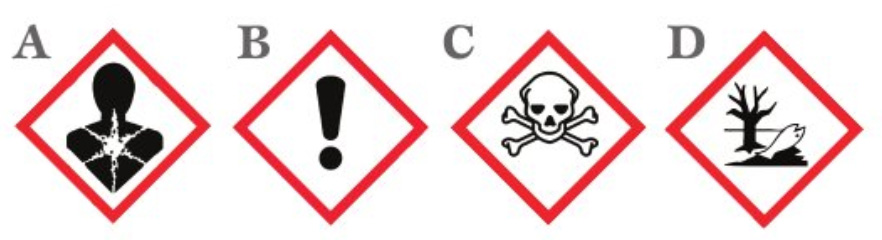

Safety Alert Symbol (Pictogram)

Compliant signs feature a single image depicting the present hazard. Some of the most common ones include:

- General health hazards (pinching, crushing, etc.)

- Explosion or ignition danger (contents stored under pressure, inflammatory materials, etc.)

- Skin, eye or respiration danger (particulate inhalation, burns, etc.)

- Hazards representing a danger to the environment or nearby wildlife

Message Panel

If the signal word is there to capture the attention of passersby, then the message panel’s intention is to elucidate why that level of awareness or preparation is required. Here are some examples:

- Confined space: Enter by permit only.

- Keep away: High-pressure pipes may cause injury or death.

- Construction area: Hard hat and ear protection are required beyond this point.

The safety manager’s task is to craft an appropriately descriptive message that leaves nothing open to interpretation. Specific and detailed language is encouraged, but not at the expense of being impactful and succinct.

Optional color-coding may accompany these message panel phrases. A blue outline around the pictogram indicates required personal protective equipment (PPE), and a black or red outline with a slash through it illustrates a prohibited item or behavior.

3. Use the Right Sign in the Right Place

There are three primary classifications for the risk severity described by safety signage. It’s important to match the sign to the type of hazard. OSHA and ANSI recognize these primary risk classifications:

- Danger: These red signs indicate a hazard nearby that will almost certainly result in death if proper procedures are not followed.

- Warning: Warning signs are usually orange and call attention to a hazard that could result in injury or death, but with a lower likelihood of occurring than the “danger” sign.

- Caution: These yellow signs indicate the chance for minor to moderate injuries if people don’t take the required safety actions. One example could be the presence of compromised air quality — a more common workplace factor than most realize.

There are several other colors and types of signs that may be relevant. They indicate to workers and visitors how to appraise their surroundings, travel about safely, find tools quickly in an emergency or get more information about a situation:

- Notices: These deliver notifications about an area, a piece of equipment or rules to follow.

- General safety signs: These may reference housekeeping, sanitation and general practices.

- Fire safety: These show the locations of emergency equipment and exits.

- Admittance: These indicate who is permitted to enter an area, who is not and under which circumstances.

- Non-hazard indicators: These may show directions to a location or provide other general building information to help control traffic or access.

Safety managers and other decision-makers must work closely with employees to find and accurately label workplace hazards. Sometimes it takes the keen eyes of a frontline worker to identify dangers the C-suite might overlook.

The resulting signage should be placed at average eye level and in a noticeable spot before accidents happen. It should alert workers as they approach a controlled or hazardous area and give them time to react and prepare accordingly.

Safety Begins with Effective Communication

People perform unseen and often underappreciated work every day. They ensure our purchases reach us swiftly and our transportation and supply-chain infrastructure function as intended. As warehouses and other workplaces strove to become leaner over the last few years, businesses quickly realized no workers should be treated as disposable assets.

These essential roles aren’t always 100% safe, but they don’t have to be overly risky. Understanding and deploying the right signage is required to keep crews safe. Effective communication is key in any workplace, and sometimes a well-chosen icon or warning phrase can say a thousand words.

Jane Marsh covers topics in green technology and manufacturing. She also works as the Editor-in-Chief of Environment.co.