OSHA 1910.29 – Criteria and Practices for Fall Protection Systems and Falling Object Protection

“Safety Rail Company manufactures the SRC360 Mobile Railing System, a free-standing, non-penetrating railing system that complies with OSHA 1910.28 and 1910.29. As a passive fall protection system, it works 24/7 and requires no significant training or worker compliance. In low-slope, commercial roofing applications, the SRC360 is an ideal solution for active fall hazard areas and can be left in place permanently to protect all trades that access the roof.” Safety Rail Company, 888-434-2720, https://safetyrailcompany.com

Each year, workplace falls injure thousands of workers – hundreds of them fatally. The construction industry generally consistently has the highest number of fall-related deaths, leading to its inclusion in the Occupational Safety and Health Administration (OSHA) “Fatal Four” list; along with struck-by incidents, caught-in or between incidents and electrocutions. Fall injuries create a tremendous financial burden for workers, their families and their employers due to costs associated with days away from work, medical costs and workers’ compensation.

About the Standard

Employers must set up the work place to prevent employees from falling off of overhead platforms, elevated work stations or into holes in the floor and walls.

OSHA requires that fall protection be provided at elevations of 4 feet in general industry workplaces, 5 feet in shipyards, 6 feet in the construction industry and 8 feet in longshoring operations. In addition, fall protection must be provided when working over dangerous equipment and machinery, regardless of the fall distance.

OSHA 1910.29 separates low-slope roofs into three zones. (A low-slope roof is defined as a roof that has a slope of less than 4 inches of fall over 12 horizontal inches.) Fall protection options are based upon the distance that the work is being performed from the edge of a roof, including:

- Zone 1: For work being performed more than 15 feet from the edge

- Zone 2: For work being performed between 6 feet and 15 feet from the edge

- Zone 3: For work performed less than 6 feet from the edge

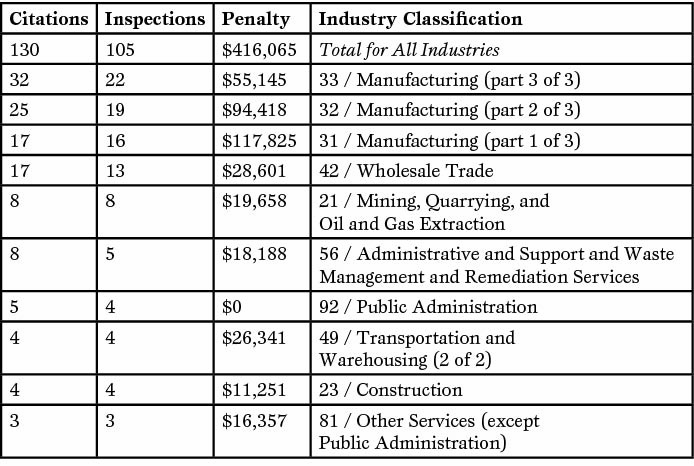

Enforcement Data

Citations regarding this standard by federal OSHA for inspections during the period October 2022 through September 2023:

Key Provisions

OSHA 1910.29 contains very specific requirements for a variety of fall protection structures, including guardrails (top edge height of top rails, strength criteria, where midrails must be installed, screen and mesh specifications, etc.); guardrail systems at hoist areas and holes; handrail and stair rail systems (measurements, finger clearances, surface types and dimensions of handrails); cages, wells, and platforms used with fixed ladders (design, construction and maintenance to permit easy access to, and egress from, the ladder that they enclose).

Employers must:

- Guard every floor hole into which a worker can accidentally walk (using a railing and toe-board or a floor hole cover).

- Provide a guard rail and toe-board around every elevated open sided platform, floor or runway.

- Regardless of height, if a worker can fall into or onto dangerous machines or equipment (such as a vat of acid or a conveyor belt) employers must provide guardrails and toe-boards to prevent workers from falling and getting injured.

Other means of fall protection that may be required on certain jobs include safety harness and line, safety nets, stair railings and hand rails.

Additional Measures to Prevent Dropped Object Incidents

The National Institute for Occupational Safety and Health[1] (NIOSH) has created a construction toolbox talk about preventing falling objects that supervisors can use when holding safety meetings with employees.

Workers should be reminded to:

- Always secure all tools in elevated work areas if they are close to leading edges

- Secure hand tools, such as with a tool lanyard or holster, to prevent them from falling to a lower level.

- Secure loads before lifting and moving them with lifts or cranes.

- Do not hoist or pass loads over people.

- Stack materials neatly to keep them from toppling over.

- Always wear a hard hat and other appropriate personal protective equipment.

View the OSHA standard at: www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.29 WMHS