Electrical Fatalities in the Workplace

By Daniel Majano and Brianne Deerwester, Contributors

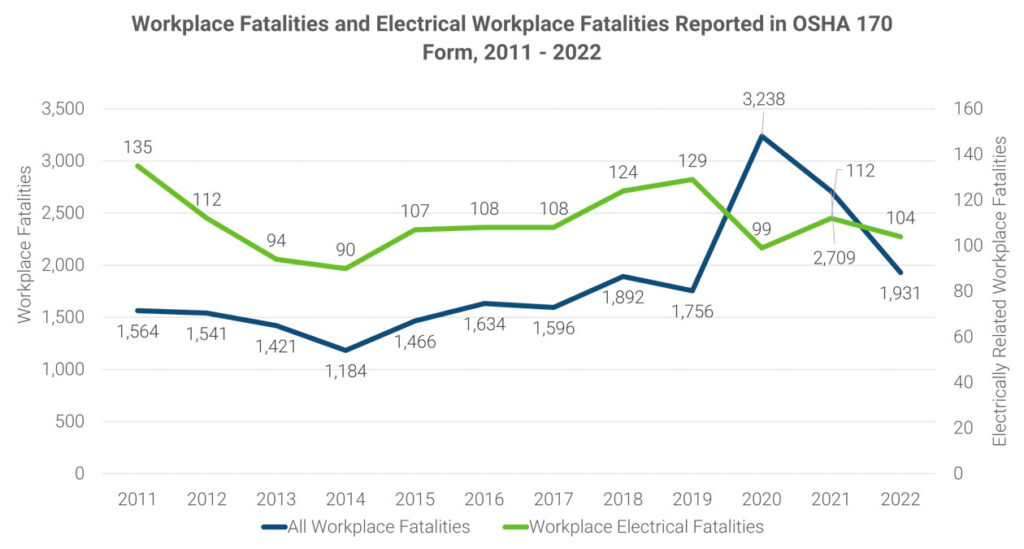

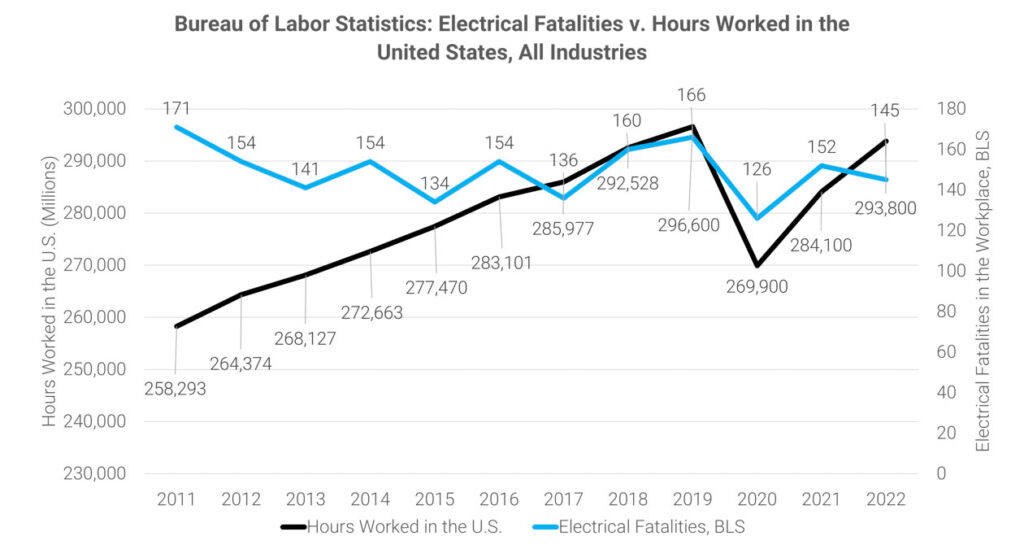

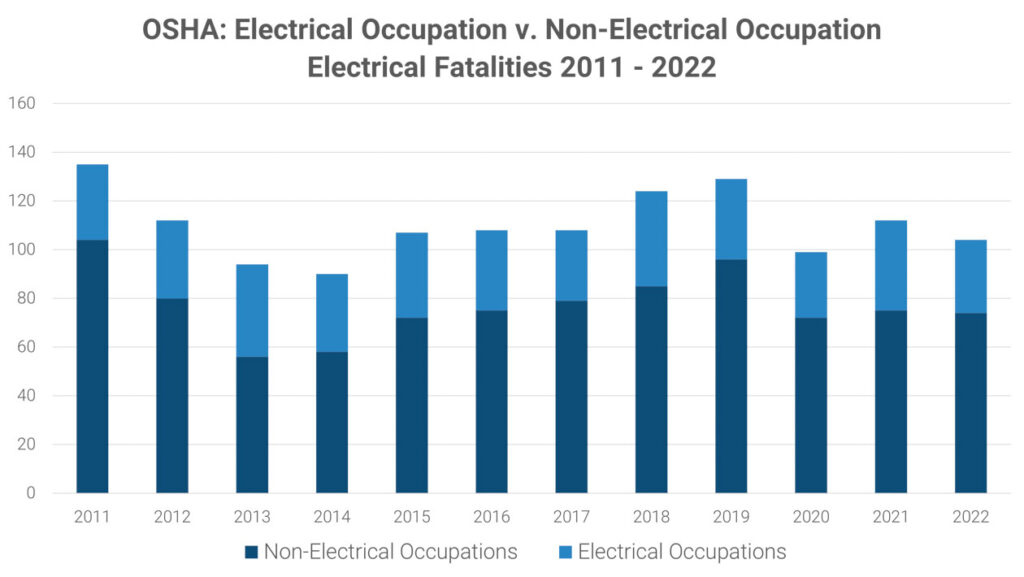

Contact with or exposure to electricity continues to be one of the leading causes of workplace fatalities and injuries in the United States. According to the Occupational Safety and Health Administration (OSHA), there were 1,322 workplace fatalities involving electricity between 2011 and 2022.

Of the workplace electrical fatalities reported to OSHA, 70% of fatalities occurred in non-electrically related occupations, while 30% of workplace electrical fatalities occurred in electrical occupations. Of all fatalities, 6% were caused by contact with electricity. Overall, there was a 1.5% average decrease in workplace electrical fatalities year over year.

Each year, the Electrical Safety Foundation (ESFI) collects information on fatal occupational electrical injuries using the U.S. Bureau of Labor Statistics’ (BLS) Census of Fatal Occupational Injuries (CFOI) and Survey of Occupational Injuries (SOII), as well as OSHA Accident Investigation reports. ESFI then publishes the information in tabular and graphical form on esfi.org. The most recent data set covers the 11 years from 2011 to 2022.

The BLS’ CFOI is an actual count, or census, of fatal injuries. Each case is verified by two or more independent sources of information. Similarly, to estimate the number of nonfatal injuries and illnesses, the BLS performs its SOII. Due to their sheer number, nonfatal injuries are statistically estimated based on a large annual survey of injuries reported by employers.

In looking at the occupations involved in electrical fatalities as reported to OSHA, the occupations with the most electrical fatalities included electricians (195 fatalities); construction laborers (119 fatalities); laborers, except construction (117 fatalities); electrical power installers and repairers (109 fatalities); tree trimming occupations (94 fatalities); HVAC and refrigeration mechanics (42 fatalities); electricians’ apprentices (37 fatalities); truck drivers, heavy (35 fatalities); roofers (29 fatalities); and painters, construction and maintenance (28 fatalities).

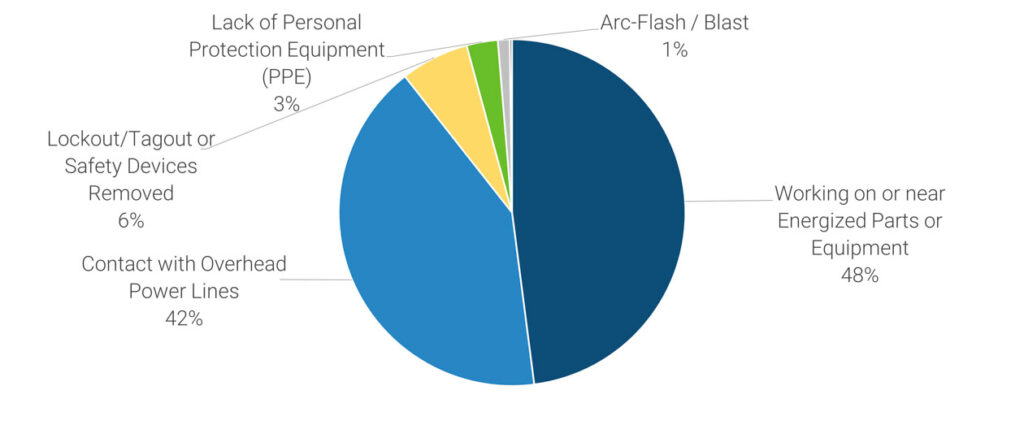

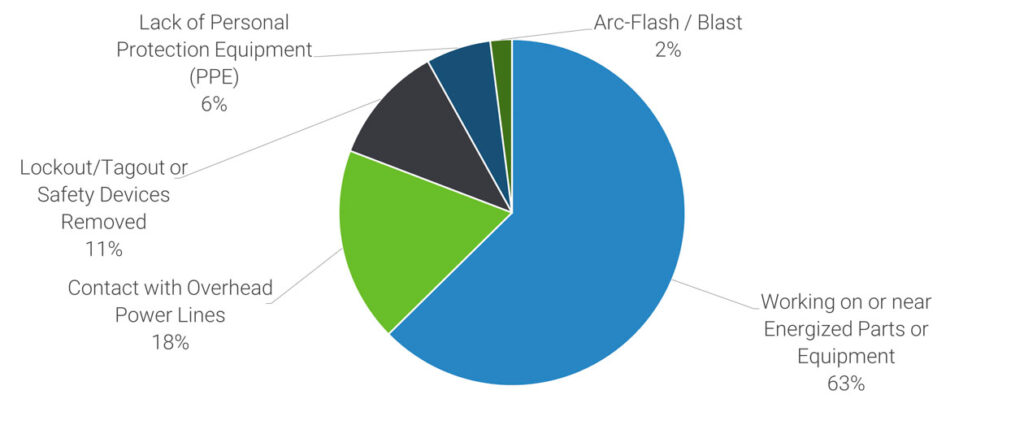

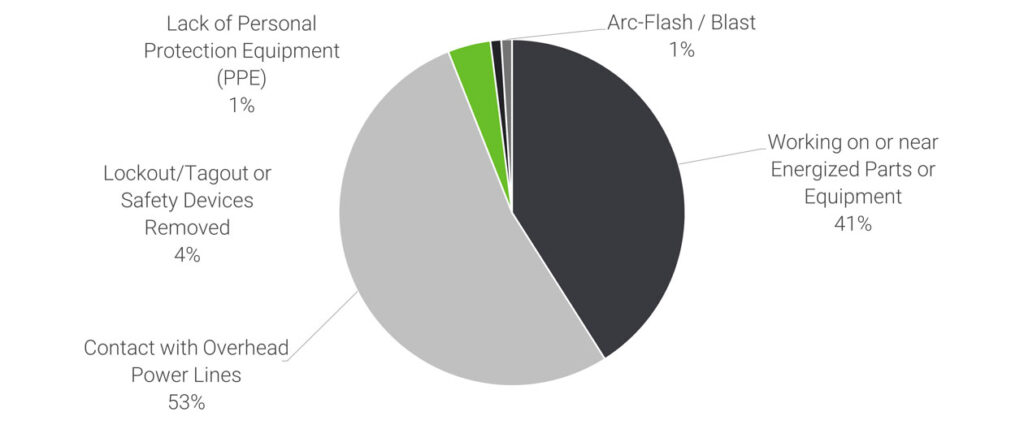

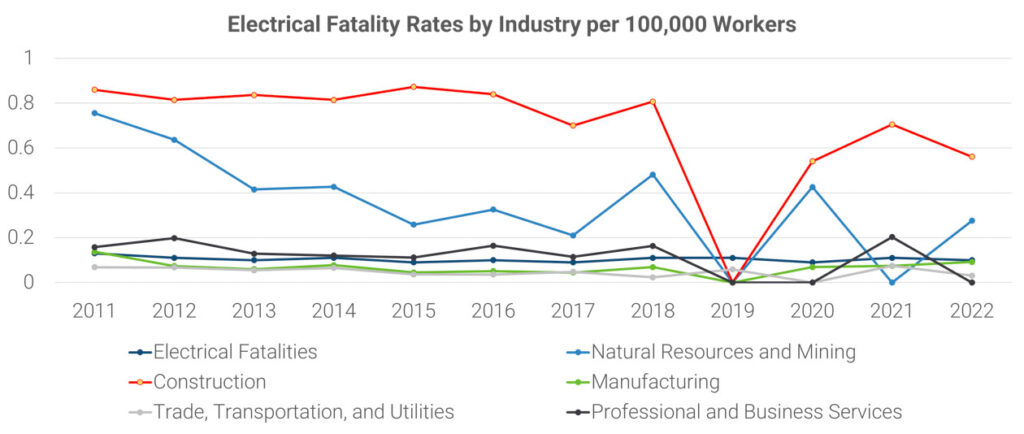

Electrical fatality causes vary based on the occupation type. In looking at the electrical fatality causes for all occupations, 48% occurred when workers were working on or near energized wires or parts, 42% from contact with overhead power lines, 6% because of lockout/tagout or safety devices removed, 3% because of a PPE issue, and 1% from an arc-flash or blast. In looking at electrical occupations, 63% occurred when workers were working on or near energized wires or parts, 18% from contact with overhead power lines, 11% because of lockout/tagout or safety devices removed, 6% because of a PPE issue, and 2% from an arc-flash or blast. In looking at non-electrical occupations, 41% occurred when workers were working on or near energized wires or parts, 53% from contact with overhead power lines, 4% because of lockout/tagout or safety devices removed, 1% because of a PPE issue, and 1% from an arc-flash or blast. The construction industry has the highest number of electrical fatalities. The top four construction hazards include falls, struck-by, caught-in/between, and electrocution.

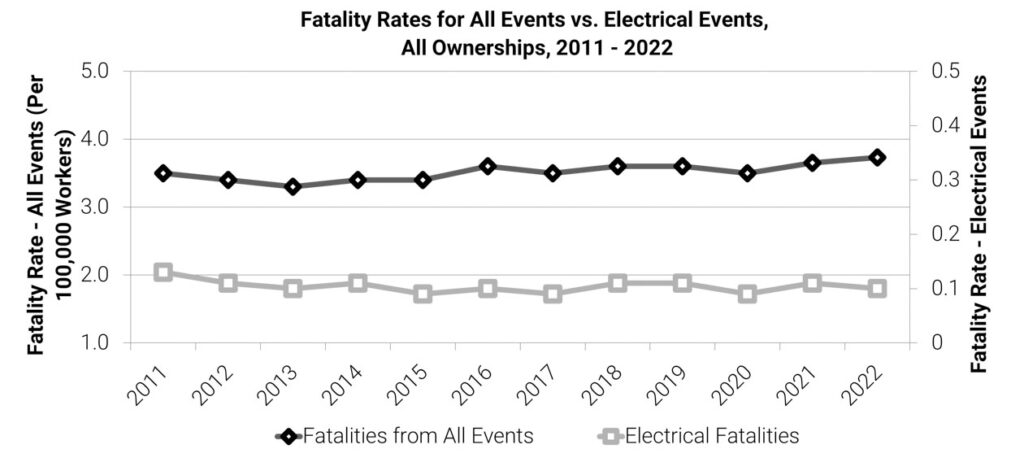

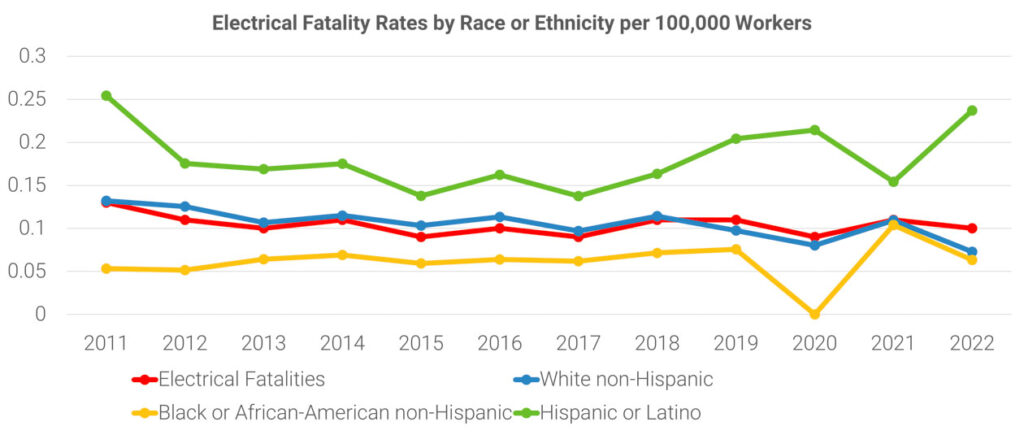

Electrical fatality rates per 100,000 workers have remained consistent while overall fatality rates have increased. Hispanic or Latino workers have the highest rate of electrical fatalities at 0.18 fatalities per 100,00 workers. White, non-Hispanic workers have 0.1 fatalities per 100,000 workers, while Black or African American, non-Hispanic workers have 0.06 fatalities per 100,000 workers. Construction and extraction occupations; installation, maintenance, and repair occupations; and building and grounds cleaning and maintenance occupations have the highest rate of electrical fatalities.

Preventing Injuries with Emerging Technologies

Between 2011 and 2022, the top cause of electrical fatalities for all occupations, electrical and non-electrical, was from workers working on or near energized parts or wires. The overwhelming majority of individuals injured on the job site are unqualified, non-electrical workers inadvertently coming into contact with electricity. These workers have little-to-no electrical safety training.

It is imperative that all workers working near electrical equipment or power lines have basic training to avoid electrical injuries. Only qualified individuals and electricians should be conducting electrical work. As advanced technology – including electric vehicle supply equipment (EVSE), energy storage systems, and photovoltaic systems – become more prevalent, it will be critical to ensure that only qualified and specially trained individuals install these systems. A recent survey conducted by ESFI found that 76% of EVSE installers said they had specific training, while 82% believed EVSE should have a designated certification.[1]

Survey respondents also shared concerns about the high voltage involved in EVSE systems. If the high voltage is not handled properly, it can lead to various safety issues, including electrocution, electrical shock, and fires. The most frequently mentioned safety concern was the risk of electrocution or electrical shock, either due to installation errors, wiring mistakes, or working with live wires. Many respondents mentioned worries about incorrect or faulty wiring, improper connections, and incorrect wire gauges. Several respondents also expressed concerns about a lack of professional training or expertise, whether in themselves or others, and the potential safety hazards this could lead to. This includes installers who are not properly trained to work with EVSE systems or who are not aware of the necessary safety precautions.

ESFI strives to keep workers safe on the jobsite. Working with electricity is extremely dangerous, therefore it is important to always hire qualified electrical workers. ESFI urges workers to know the limit of their qualifications to avoid electrical injuries and fatalities. It’s imperative to stop and reassess a situation if there is a doubt about a task or a procedure requirement. Knowing when to say “when” and stop work can save your life and the lives of those around you. For more information and to utilize ESFI’s free workplace safety resources, including infographics, full-length videos, and video shorts, visit esfi.org.

Daniel Majano is the Program Manager, Electrical Safety Foundation (esfi.org).

Brianne Deerwester is the Communications Coordinator, Electrical Safety Foundation (esfi.org).

[1] https://www.esfi.org/electric-vehicle-supply-equipment-survey/