OSHA-Required Fall Protection Inspections

By Mark C. Conover, Contributor

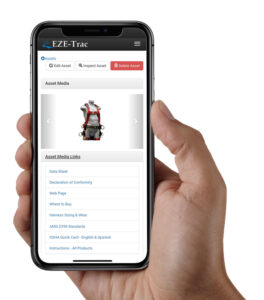

With the use of your smart device, scan the RFID or QR code on your fall protection equipment, or other asset, and it’s automatically input to your cloud-based software.

We all know that “personal fall arrest systems shall be inspected prior to each use…” [OSHA 1926.502(d)(21)]. But did you know that OHSA and ANSI require annual inspections on all fall protection equipment by a competent person? What’s more, OSHA requires these inspections to be documented. While most of us already know this, do you have a good way of tracking and efficiently recording these inspections on a timely basis? Well, there are new ways that can help you make safety inspections, asset management, and documentation much less burdensome.

When I ask most safety professionals how they do their annual competent person safety inspections I get a variety of responses from, “We have a written file…”; “We record ours on an Excel spreadsheet…”; to “My assistant compiles the info…”. Regardless of how you document your competent person inspections I most invariably hear “It’s a pain!” Well, it does not have to be.

Asset Management and Safety Inspection Software

Technology has given us the mobile phone and by now most everyone has a smartphone. Can you imagine being able to do your annual personal fall arrest inspections on your smartphone or tablet at the jobsite and store your documentation on the cloud in a matter of minutes? Also, can you imagine having several jobsites around town, around the state, throughout the country/the world and using the same cloud-based system for asset management and safety inspections? If you can imagine it, it is probably available to you now. This is simply made possible by the use of RFID/QR code tracking tags, and Asset Management and Safety Inspection Software. Several fall protection companies already install RFID tracking tags on their products. With the use of your smart device, scan the RFID or QR code on your fall protection equipment, or other asset, and it’s automatically input to your cloud-based software. Your asset inventory and safety inspection can be a breeze.

It sounds simple, and it is. What makes it easy is the hardware is already available to you with your smart device or laptop. You no longer need to bring the equipment into a central location to do these asset management and safety inspections. You can keep your competent person in the field being productive and having your asset/safety inspections being done on time. With reminders from the cloud-based software there is no reason for delayed inventory or inspections, and your results are instantaneous. In addition, most RFID systems can offer limited or unlimited multiple authorized user platforms. But note that software flexibility or cloud storage may vary by vendor, and some RFID systems are not as flexible as others. Your research will let you know what fits your company’s needs.

What you should look for in a RFID/QR code Asset Management and Safety Inspection Software:

- RFID and QR code capable system- Some smartphones and tablets cannot read RFID. All smartphones can read QR code.

- Flexible system- Do I have the ability to use multiple vendor products, and can I add asset management to the system?

- Cloud-based Software- Can I access the software from anywhere and is the info I input limited?

- Additional RFID/QR Code tracking tags available- Some vendors offer additional tags for asset management tracking.

Inspecting harnesses, self-retracting devices, and other fall protection equipment is critical to employee safety and OSHA compliance but is time consuming and easily ignored. This is why an RFID/QR code equipment tagging system can be time-saving and critical to your jobsite safety and asset management success. With electronic reminders set from your cloud-based software you can record safety training dates and send out notices of expiring certificates, or even driver’s licenses. You’re able to conduct inspections in a fraction of the time it would take with paper forms or spreadsheets. You can save and recall all inspections, from anywhere, in real time. No double entry. No missed inspections. No keeping track of paper forms. Make your inspection documentation painless for all involved. CS

Mark C. Conover is the National Sales Manager for Elk River, Inc. (www.elkriver.com). Conover is a 20-year veteran in fall protection working in sales and represents Elk River on the ANSI Z359 Fall Protection Code committee. Elk River, Inc is a leading U.S. manufacturer of personal fall protection equipment to construction and general industry.